News

Provide a complete set of wear-resistant and long-lasting solutions for your production

Creation time:2025-07-23 View:1024

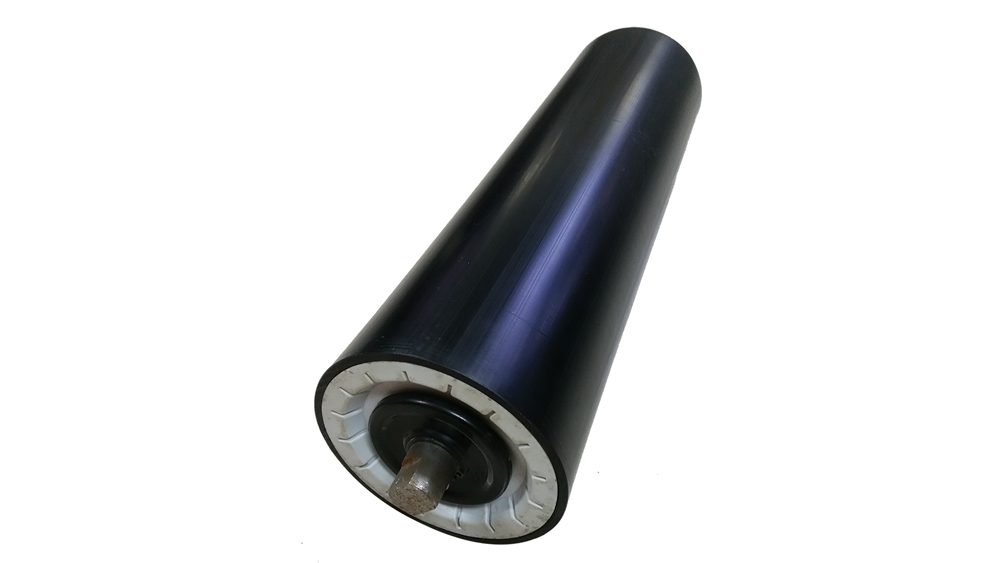

In the dynamic landscape of industrial equipment, the choice of components can significantly impact performance, durability, and overall operational efficiency. Among the many innovative solutions available, Ultra-High Molecular Weight Polyethylene (UHMWPE) rollers have emerged as a game-changer, offering a plethora of advantages that make them a preferred choice across diverse industries. This article delves into the world of UHMWPE rollers, exploring their unique properties, applications, and the reasons why they are revolutionizing the way we approach material handling and conveyance.

UHMWPE is a remarkable thermoplastic polymer renowned for its extraordinary molecular weight, typically ranging from 3 to 6 million. This high molecular weight gives rise to a host of exceptional properties that set UHMWPE apart from traditional materials. The long, entangled molecular chains contribute to its outstanding toughness, impact resistance, and wear resistance, making it an ideal material for applications where durability and reliability are paramount.

One of the most notable features of UHMWPE rollers is their remarkable wear resistance. In industrial settings where materials are constantly being conveyed, rubbed, or scraped, wear and tear can take a toll on equipment, leading to frequent replacements and costly downtime. UHMWPE rollers, however, can withstand even the harshest abrasive conditions, outlasting traditional metal or rubber rollers by a significant margin. Their smooth surface and low coefficient of friction reduce the likelihood of material adhesion and abrasion, ensuring a longer lifespan and reduced maintenance requirements.

In addition to their wear resistance, UHMWPE rollers exhibit exceptional impact resistance. They can absorb and dissipate high levels of energy without cracking, breaking, or deforming, making them suitable for applications where sudden impacts or heavy loads are common. This property is particularly valuable in industries such as mining, construction, and manufacturing, where equipment is often subjected to rigorous operating conditions.

UHMWPE rollers possess inherent self-lubricating properties, which means they require little to no external lubrication to operate smoothly. This not only reduces maintenance costs but also eliminates the risk of lubricant contamination in sensitive applications. The low coefficient of friction between UHMWPE and other materials allows for easy movement and efficient material handling, minimizing energy consumption and maximizing productivity.

UHMWPE is highly resistant to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. This makes UHMWPE rollers suitable for use in industries such as chemical processing, food and beverage, and pharmaceuticals, where exposure to harsh chemicals is a daily occurrence. Their chemical resistance ensures long-term reliability and performance, even in the most challenging environments.

Another advantage of UHMWPE rollers is their low moisture absorption rate. Unlike some materials that can swell or degrade when exposed to moisture, UHMWPE remains stable and unaffected, maintaining its mechanical properties over time. This makes it an ideal choice for applications in humid or wet environments, such as in the marine, agricultural, and wastewater treatment industries.

The versatility of UHMWPE rollers makes them suitable for a wide range of applications across various industries. Some of the key areas where UHMWPE rollers are commonly used include:

In conveyor systems, UHMWPE rollers play a crucial role in ensuring smooth and efficient material movement. Their wear resistance, self-lubricating properties, and low friction coefficient make them ideal for use in belt conveyors, roller conveyors, and gravity conveyors. UHMWPE rollers can handle a variety of materials, from lightweight packages to heavy bulk materials, without causing damage or wear to the conveyor belt.

In the packaging industry, UHMWPE rollers are used in packaging machines to transport and position products during the packaging process. Their smooth surface and precise dimensional tolerances ensure accurate product placement and minimize the risk of product damage. UHMWPE rollers are also resistant to the chemicals and adhesives commonly used in packaging, making them a reliable choice for this industry.

The food and beverage industry has strict hygiene and safety requirements, and UHMWPE rollers meet these standards with flying colors. Their non-toxic, non-stick, and easy-to-clean properties make them ideal for use in food processing, bottling, and packaging equipment. UHMWPE rollers are also resistant to the acids and alkalis used in food and beverage production, ensuring long-term durability and performance.

In the textile industry, UHMWPE rollers are used in spinning, weaving, and finishing machines to transport and guide fabrics. Their low friction coefficient and smooth surface prevent fabric snagging and damage, resulting in higher-quality products. UHMWPE rollers are also resistant to the oils and chemicals used in textile processing, making them a reliable choice for this industry.

The automotive industry uses UHMWPE rollers in various applications, such as in conveyor systems for automotive assembly lines and in the production of automotive components. Their high strength, wear resistance, and impact resistance make them suitable for use in harsh automotive manufacturing environments. UHMWPE rollers also help to reduce noise and vibration in automotive equipment, improving the overall driving experience.

There are several compelling reasons why UHMWPE rollers are becoming increasingly popular in industrial applications:

Although UHMWPE rollers may have a higher initial cost compared to some traditional materials, their long lifespan and low maintenance requirements result in significant cost savings over time. By reducing the need for frequent replacements and minimizing downtime, UHMWPE rollers can help businesses improve their operational efficiency and reduce overall costs.

The unique properties of UHMWPE rollers, such as their wear resistance, impact resistance, and self-lubricating capabilities, contribute to improved performance and productivity in industrial processes. By ensuring smooth and efficient material handling, UHMWPE rollers can help businesses increase throughput, reduce waste, and enhance the quality of their products.

UHMWPE is a recyclable material, making UHMWPE rollers an environmentally friendly choice. By choosing UHMWPE rollers, businesses can reduce their environmental impact and contribute to a more sustainable future. Additionally, the energy-efficient operation of UHMWPE rollers helps to minimize energy consumption, further reducing their carbon footprint.

UHMWPE rollers can be customized to meet the specific needs of different applications. They can be manufactured in various sizes, shapes, and colors, and can be tailored to have specific properties, such as increased hardness or enhanced chemical resistance. This flexibility allows businesses to optimize the performance of their equipment and ensure that it meets their exact requirements.

In conclusion, UHMWPE rollers offer a wide range of benefits that make them a superior choice for industrial applications. Their exceptional wear resistance, high impact resistance, self-lubricating properties, chemical resistance, and low moisture absorption rate make them suitable for use in a variety of industries and applications. By choosing UHMWPE rollers, businesses can improve the performance, durability, and efficiency of their equipment, while also reducing costs and minimizing their environmental impact. As technology continues to advance, it is likely that we will see even more innovative applications for UHMWPE rollers in the future.

If you are looking for high-quality UHMWPE rollers for your industrial needs, look no further than Jinan Soaring International Trade Co., Ltd. With years of experience in the industry and a commitment to excellence, we offer a wide range of UHMWPE products that are designed to meet the highest standards of quality and performance. Contact us today to learn more about our products and how we can help you optimize your industrial processes.