News

Provide a complete set of wear-resistant and long-lasting solutions for your production

Creation time:2025-08-14 View:1027

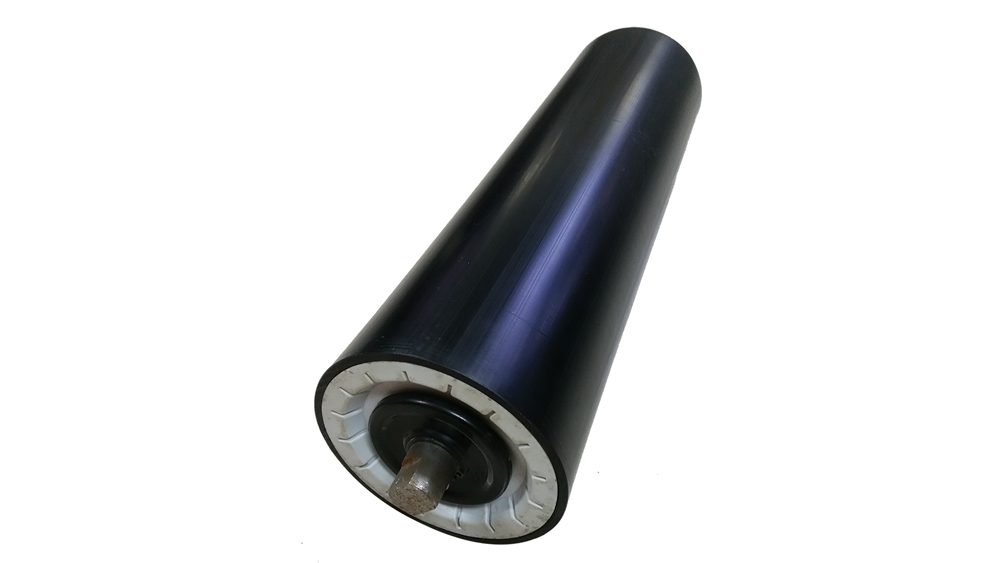

In the realm of belt conveyor systems, high molecular weight polyethylene idlers stand out as crucial components, especially when provided by reliable sources like Jinan Soaring International Trade Co., Ltd. These idlers play a fundamental role in ensuring the smooth and efficient operation of conveyor belts across various industries.

High molecular weight polyethylene, with a molecular weight typically above 3 million, exhibits a unique set of properties. It is highly wear-resistant, far surpassing many traditional materials. In fact, it has been shown to be 5 to 7 times more wear-resistant than carbon steel or stainless steel in relative conditions. This exceptional wear resistance significantly extends the service life of the idlers, making them a cost-effective choice in the long run.

The material also demonstrates remarkable impact resistance. Its molecular structure, featuring a coiled linear arrangement, endows it with an extremely high impact strength. This is why it has been used in applications such as bulletproof vests and armored protection in many countries. When applied to idlers, this property ensures that they can withstand long-term rotation, as well as accidental drops or impacts without breaking.

Another outstanding characteristic is its self-lubricating property. The friction coefficient of high molecular weight polyethylene is extremely low, similar to that of an ice surface. As the surface of an idler, this property effectively reduces friction with the conveyor belt, which in turn prolongs the lifespan of the belt. This not only reduces maintenance costs but also minimizes the risk of belt damage due to excessive friction.

High molecular weight polyethylene is highly resistant to corrosion. Under normal temperature conditions, it remains chemically inert and is hardly affected by acids, alkalis, salts, sulfur, or other corrosive media. This corrosion resistance eliminates concerns about idler corrosion and rust, even in harsh working environments.

With an extremely low water absorption rate of only about 0.01%, high molecular weight polyethylene has excellent anti-adhesion properties. Even in the presence of water or oil, dust and other materials are unlikely to adhere to its surface and form deposits. For idlers, this means that there is no need to worry about the surface adhering to materials and biting the belt, nor about the increased rotational resistance caused by deposits in the rotating parts.

Furthermore, this material is lightweight, with a specific gravity of approximately 0.94, which is only about one-eighth that of carbon steel. As a result, the installation and replacement of high molecular weight polyethylene idlers are relatively easy and convenient. Additionally, they operate with minimal noise, reducing the overall noise level in the working environment and creating a more comfortable and quieter workplace.

In belt conveyor systems, high molecular weight polyethylene idlers offer several significant advantages. Their long service life, attributed to high wear resistance and impact resistance, reduces the frequency of idler replacements. This leads to fewer system downtimes, ensuring continuous and efficient material transportation.

The low friction coefficient of the idler surface, due to its self-lubricating property, helps to reduce the driving power required for the conveyor belt to operate. This not only saves energy but also places less stress on the conveyor's motor and other components, extending their lifespan as well.

The anti-corrosion and anti-adhesion properties of high molecular weight polyethylene make these idlers suitable for use in a wide range of industries, including those with harsh operating conditions. In industries such as mining, where the environment is often dusty and corrosive, and in the chemical industry, where exposure to various corrosive substances is common, these idlers can maintain their performance over an extended period.

High molecular weight polyethylene idlers find extensive applications in multiple industries. In the mining industry, they are used in conveyor systems for transporting ores and coal. Their high wear resistance and impact resistance make them well-suited to handle the rough and heavy materials in this industry. Additionally, in some cases, they can be designed to have anti-static and non-halogen flame-retardant properties, ensuring safety in potentially explosive environments such as coal mines.

In the cement industry, these idlers play a crucial role in conveyor systems for transporting cement and raw materials. Their anti-adhesion property prevents the adhesion of cement dust and particles to the idler surface, avoiding issues such as belt deviation and reduced conveyor efficiency.

At ports and docks, where conveyor systems are used for handling a large volume of goods, high molecular weight polyethylene idlers prove their worth. Their corrosion resistance allows them to withstand the salty and humid coastal environment, ensuring reliable operation over time.

In conclusion, high molecular weight polyethylene idlers provided by Jinan Soaring International Trade Co., Ltd. are essential components for belt conveyor systems. Their unique material properties translate into numerous advantages in terms of performance, durability, and energy efficiency, making them suitable for a wide range of industrial applications. As industries continue to seek more efficient and reliable conveyor solutions, these idlers are set to play an even more significant role in the future.