News

Provide a complete set of wear-resistant and long-lasting solutions for your production

Creation time:2025-07-03 View:1032

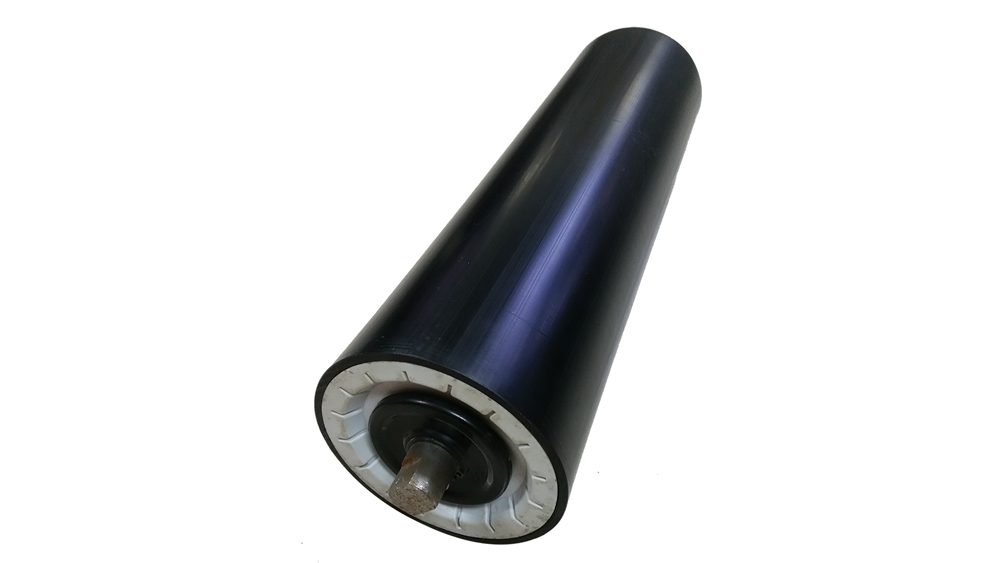

In the dynamic world of industrial machinery and material handling, the choice of components can significantly impact the efficiency, durability, and overall performance of your operations. Among the various options available, UHMWPE (Ultra-High Molecular Weight Polyethylene) rollers stand out as a game - changing solution, and Jinan Soaring International Trade Co., Ltd. is at the forefront of providing high - quality UHMWPE roller products.

UHMWPE is a remarkable thermoplastic with an extremely high molecular weight, typically in the range of 3 - 6 million. This unique molecular structure endows it with a host of extraordinary properties that make it an ideal material for roller applications.

One of the most notable features of UHMWPE is its outstanding wear resistance. In fact, it has the highest wear resistance among all plastics and even surpasses some metals. When used in rollers, this property ensures a significantly extended service life, even in harsh operating conditions where there is continuous friction and abrasion. For example, in industries such as mining, where rollers are constantly exposed to abrasive materials like ores and rocks, UHMWPE rollers can withstand the wear and tear far better than traditional materials. This not only reduces the frequency of roller replacements but also minimizes downtime, leading to increased productivity.

UHMWPE rollers exhibit excellent impact resistance. They can absorb and dissipate high - energy impacts without cracking or breaking. This is crucial in applications where the rollers may be subjected to sudden shocks, such as in conveyor systems handling heavy or irregularly shaped objects. Whether in a manufacturing plant moving large components or in a logistics facility dealing with heavy pallets, UHMWPE rollers can handle the impacts, maintaining their integrity and performance over time.

UHMWPE has a very low coefficient of friction, typically in the range of 0.05 - 0.11. This, combined with its self - lubricating nature, makes it an ideal material for rollers. When in operation, UHMWPE rollers reduce the energy required to move materials, resulting in energy savings. The self - lubricating property also means that there is no need for frequent external lubrication, which simplifies maintenance and reduces the risk of contamination from lubricants. In food and pharmaceutical industries, where hygiene is of utmost importance, this feature is particularly valuable as it ensures a clean and safe operating environment.

UHMWPE is highly resistant to a wide range of chemicals, including acids, alkalis, and many organic solvents. This chemical inertness makes UHMWPE rollers suitable for use in industries such as chemical processing, where they may come into contact with corrosive substances. In a chemical plant, for instance, UHMWPE rollers can be used in conveyor systems transporting chemical products without being affected by the chemicals, ensuring reliable and long - lasting operation.

Another advantage of UHMWPE is its low moisture absorption rate. It hardly absorbs any water, which means that UHMWPE rollers will not swell or degrade when exposed to humid environments. This makes them suitable for use in industries such as paper and pulp, where the operating environment may be wet, or in outdoor applications where they are exposed to rain and moisture.

The unique properties of UHMWPE rollers make them suitable for a diverse range of applications across various industries.

In conveyor systems, which are widely used in industries such as manufacturing, logistics, and mining, UHMWPE rollers play a crucial role. Their high wear resistance ensures long - term operation, while the low friction coefficient allows for smooth movement of goods. In a large - scale e - commerce fulfillment center, for example, conveyor systems with UHMWPE rollers can efficiently transport packages of different sizes and weights, reducing the likelihood of jams and breakdowns.

In the food and beverage industry, hygiene and safety are top priorities. UHMWPE rollers are non - toxic and easy to clean, meeting the strict hygiene requirements of this industry. They are used in conveyor systems for food processing, bottling, and packaging. For instance, in a beverage bottling plant, UHMWPE rollers can be used to transport bottles without leaving any residue or contaminants, ensuring the quality and safety of the products.

In the textile industry, UHMWPE rollers are used in machinery for tasks such as fabric winding and yarn processing. Their low friction coefficient helps to prevent damage to delicate fabrics and yarns, while their wear resistance ensures reliable operation in the long run. In a textile mill, UHMWPE rollers can contribute to the smooth production of high - quality textiles.

In the printing and packaging industry, UHMWPE rollers are used in equipment such as printing presses and packaging machines. Their ability to withstand continuous use and provide smooth movement is essential for the accurate transfer of materials and the efficient operation of these machines. In a printing house, UHMWPE rollers can help ensure precise registration of printed materials, resulting in high - quality prints.

Jinan Soaring International Trade Co., Ltd. is committed to providing top - quality UHMWPE roller products that meet the diverse needs of customers.

The company sources high - grade UHMWPE materials and employs advanced manufacturing processes to ensure that each roller meets strict quality standards. Stringent quality control measures are implemented throughout the production process, from raw material inspection to final product testing, to guarantee the performance and reliability of the UHMWPE rollers.

Recognizing that different industries and applications have unique requirements, Jinan Soaring International Trade Co., Ltd. offers customization services. Whether it's a specific size, shape, or additional features, the company can work with customers to develop UHMWPE rollers that are tailored to their exact needs. This flexibility allows customers to optimize the performance of the rollers in their specific applications.

Despite the high quality of its products, Jinan Soaring International Trade Co., Ltd. offers competitive pricing. The company aims to provide cost - effective solutions without compromising on quality, making its UHMWPE rollers an attractive option for businesses looking to enhance their operations while keeping costs under control.

The company has a dedicated team of customer service professionals who are ready to assist customers at every stage, from product consultation to after - sales support. Whether you have questions about product selection, installation, or maintenance, the team is committed to providing prompt and helpful responses to ensure a seamless experience for customers.

In conclusion, UHMWPE rollers offer a wide range of advantages that make them an ideal choice for various industrial applications. With Jinan Soaring International Trade Co., Ltd.'s high - quality products, customization options, competitive pricing, and excellent customer service, you can be confident in finding the perfect UHMWPE roller solution for your business needs. Explore the world of UHMWPE rollers today and experience the difference they can make in your operations.